Page 1 of 1

Heating your WVO barrel

Posted: Mon Apr 14, 2008 11:02 am

by delicat

I'm in the process of sourcing "heat" for the WVO during the filtration process.

I've read how people are talking about using hot water tank element to heat the oil but haven't really heard of any results...

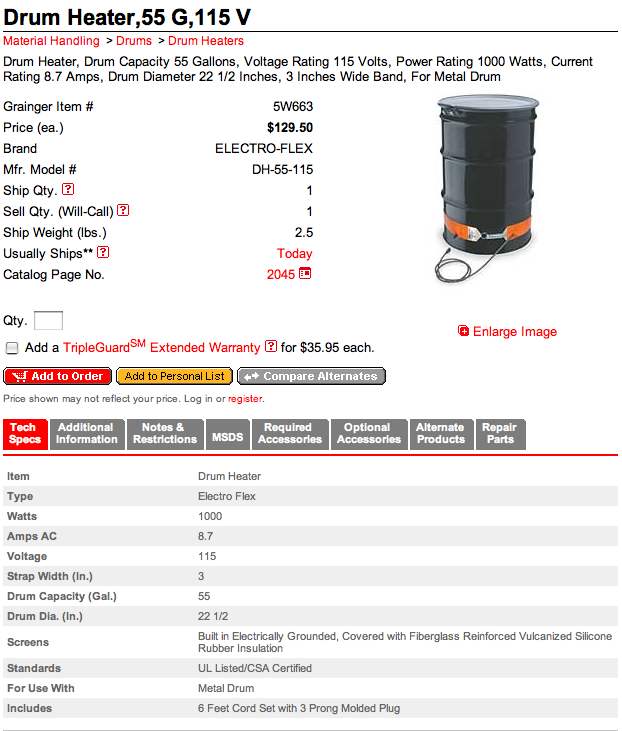

Is anyone using a barrel band heater? From info gathered on other site they would heat a 55G drum of WVO to 120F in about 8hrs. Since I have nothing to refer to I don't know if it's a decent/efficient idea or not? There's many options for those (500W to 1500W with 3" to 4" band width...) And the price goes from$130 to over $200.

- Barrel band heater.jpg (61.92 KiB) Viewed 4697 times

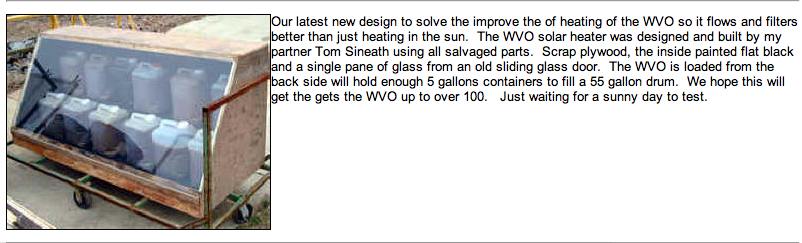

I like this custom made heating/storage for the 5G jugs:

- WVO heating storage.jpg (43.42 KiB) Viewed 4695 times

My understanding is that once you collect your oil you let it sit for a few weeks then start the filtration process but in order to get it efficiently through your 10u filter it needs to be close to 120F. Hence my initial post...

Thanks!

Re: Heating your WVO barrel

Posted: Mon Apr 14, 2008 12:07 pm

by BCDelica

55G drum of WVO to 120F in about 8hrs

A 1000 watts for 8 hours and only 50c, will help for filtering but won't de-water. Common choices are the highest wattage water heating element used as an immersion heater or permanently mounted into the barrel. Do you have 220 v service available David? My heater was(is) a 1600 120 volt element with a custom aluminum heated shield clamped onto it for safety; which failed (the clamped slipped, heat, handling and aluminum fatigue took there toll) after 2 plus years of use melting a tiny hole into the bottom corner of the blue plastic barrel.

Which brings up the other item of concern in designing your processing system - spill containment. Just where is a gallon, or 50 gals, of hot WVO going to go if containment fails!

There's ones available up to a whooping 2500w.

Re: Heating your WVO barrel

Posted: Mon Apr 14, 2008 12:36 pm

by Adam

I was using one of those shielded drop in heaters as well, not sure on the wattage, but it only seemed to heat the top layer of oil. I'd still be using it if it was working, something is better than nothing.

I like the passive solar heating option. I'll have to build that next year when I'm rid of my pesky neighbours. I think you'd need the 1500W belt to get the oil hot enough, depending on the ambient air temp, 500W doesn't sound like enough.

Utah biodiesel sells the 1200W version for heating WVO barrels. These look like a great option safe option. I'm also looking at the hot water tank heating element option, which is much cheaper, but you can't switch it between barrels, it would make the barrels more complicated to clean, and it doesn't feel as safe.

Re: Heating your WVO barrel

Posted: Mon Apr 14, 2008 1:49 pm

by delicat

I mentioned 120F (or 50C) as I was told it's a decent temperature to get the oil flowing easily through the 10u filters but wasn't thinking about the de-watering aspect.

What temperature should I get the oil going for de-watering? Would letting it sit for 2 weeks be a good start or do I really need high temperature? These barrel band heater can go up to 400F but that would take some time!

Kevin, don't have 220 in my garage. Might be able to run it but that's another project!

Thanks.

David

Re: Heating your WVO barrel

Posted: Thu Apr 17, 2008 7:06 am

by after oil

i use a fifty gallon drum w/ removeable lid. the type that has a band clamp that levers it shut to seal the lid on. i got the barrel at the bulk fuel plant. it was a grease barrel, but the drum was lined with a plastic bag so it was totally clean.

cost: $50 barrel deposit

i bought a 220V hot water heater element. the kind that screws in to the water heater. i brazed a pipe fitting into a hole near the bottom of the barrel and the heater just screws in . voila!

i wired a cord out of an appropriate circuit in the panel in my shop and a cord from the heaer. i simply plug it in.

i can heat a half barrel of oil enough to dewater in about an hour or less. i can hear the water popping and i let it go untill the popping stops. the oil just starts to smoke a little, i almost cant even see the smoke.

there is also a fitting brazed in to plumb up a 3/4" ball valve and there is a hose to a pump which then pumps through filters into my 1000L tote

im going away for a little while but maybe ill start a thread and post photos sometime early next month. but by then hopefully ill be busy with my chamonix and fixing it up to comply!