Shepherd wrote:Il check back.

I have managed to find some info I wrote about torsion bars a while ago:

CLICK HERE. This might be of some help??

If you don't make the special 'torsion bar socket' tool mentioned in that post, then I find 17mm ring spanners best for the drivers side and 17mm open ended for the passenger side.

Are you looking to go lift the motor back to 'standard' ride height or jack the front up even more?? Either way, I'll bet the passenger side is sitting slightly lower than the driver’s side? If not, you are lucky! :lol:

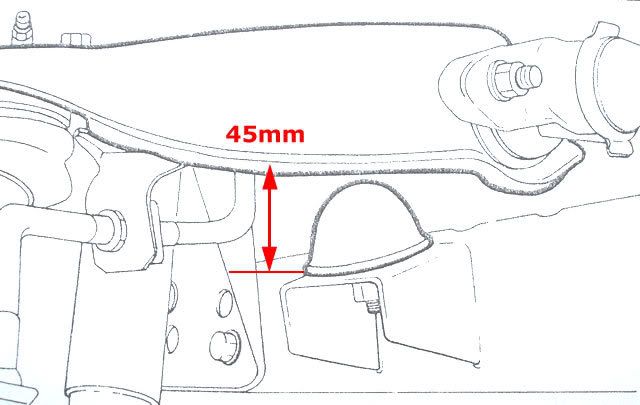

If you are going back to ‘standard’ height, then adjust the torsion bars until the clearance/distance between the upper bumpstop and the upper suspension arm is the same as the picture below:

To do the torsion bars even higher, I usually park the motor on flat level ground and measure the height of the centre of the wheelarch directly above the centre of the wheel. Do this for the rear of the vehicle first to get a comparison of how low the front is. I always measure the distance from the centre of the wheel hub to the bottom edge of the centre of the wheelarch.

Once you have the height of the rear, measure the front so you know how far to come up. You don’t want the front to be higher than the rear, so bear this in mind…. ;)

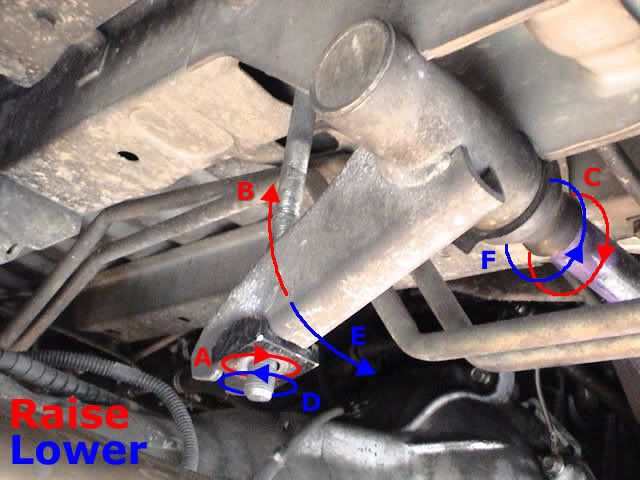

Under the vehicle (and using the photo I posted last night!) crack off the lock nut a few turns then measure the distance from the bottom of the adjuster nut to the bottom of the adjuster bar (the long threaded bar)

Adjust the nut up anywhere between 10mm and 15mm then tighten up the lock nut. 10mm adjustment equates to 15-25mm of lift (depending on how worn/sagging your torsion bars are!) Do the same for the other side, but if this side was lower, then add a little more adjustment to try and make it more even…..

Now take the motor for a 5 – 10 mile drive to let it all settle down and come back to the flat/level ground and re-check your measurements. You may need to adjust them a few times in this way until you are happy with the ride height….

As mentioned in my other post (not the one above, but the one I’ve linked to) you may need to cut the upper bump stops down if you lift the torsion bars a lot – but this is a really easy job! 8)

Once you have finished adjusting the torsion bars, make double sure that the lock nuts are nice & tight and everything is sitting nice & level…..now enjoy a better ride and better braking! :D

Regards,

Bruce.