There's a couple of writeups (with pictures) here:

http://delicapumprepair.blogspot.co.nz/ ... pair.html

...and here

http://www.mdocuk.co.uk/forums/viewtopic.php?t=26178

(The MDOCUK post is reproduced below for posterity)

I have been meaning to get this done for ages...

Well Chiefie (Rick) was kind enough to offer to show me how to do it,

Seeing as he his ex-mitsi I took the camera, Delica and seal up to Fleetwood !!

Here are my "findings"

Firstly big thanks to Rick for showing me what to do... to be fair he did most of the work !!!

How long a Job... for Rick 4 hours... me.. probably about 5.

It really is not a hard job at all, but you do need to have more than a basic knowledge of spanners.

Also a good tool box with ratchet and stubby spanners will help !

This is not a step by step guide... if you need a step by step then this is not the job for you !

If you get it wrong then you only find out when you try and start it... so thats another 5 hours to put right !!!!!

So...

here are some pics to help those of you who are tempted...

feel free to ask questions...

starting off...

- BeforeRemovalMedium-1.jpg (317.52 KiB) Viewed 11826 times

TDC.. DO NOT USE THE PULLEY !!!!

You can remove the rocker cover and use the marks on the cam shaft they have to be right..

OR

You can use the notch on the flats of the camshaft...

You do not want the flats "flat" rather you want the cut out notch as high as pssible... like this

- TDCMedium.jpg (209.07 KiB) Viewed 11826 times

bit hard to see but when you look it makes more sense, keeps the rocker cover on and the job cleaner !!

Vacume and oil pump out the way

- OilandVacumepumpRemovedMedium.jpg (296.44 KiB) Viewed 11826 times

if you look closley you can see a brass coloured nut down were the A/C belt tensioner is.

you can access the bolt with the A/C tensioner in situ and untouched, the bolt will withdraw but not remove.

Pump Out... note how little we actualy have to move out the way !!

- PumpRemovedMedium.jpg (348.86 KiB) Viewed 11826 times

Here is the mounting face were the pump goes...

- PumpMountMedium.jpg (290.03 KiB) Viewed 11826 times

the fuel pipes come off easy enough just mark them so you know which goes were....

working at the rear of the pump just take them off one at a time starting at the eaiest one.. number 1 !!

Now the hardest part is getting the bolts on the bracket under the pump.. they are 14mm and need a wobble extension bar....

here are the holes on the block

- HolesinBlockMedium.jpg (304.96 KiB) Viewed 11826 times

and on the pump the bracket...

- BottomofPumpMedium.jpg (307.28 KiB) Viewed 11826 times

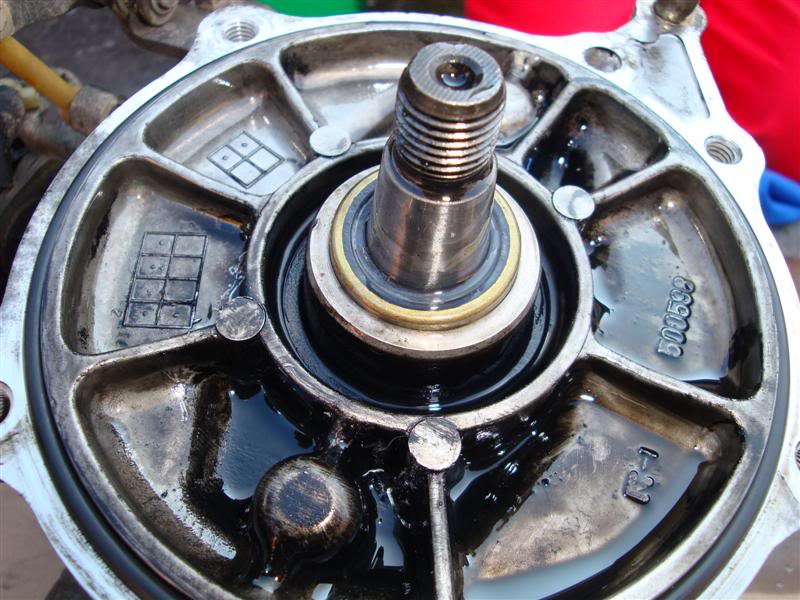

Old seal removed .... be vary carefull as that pump is made from very very soft alloy !!! do not screwdriver between the seal and the case !!

- SealRemovedMedium.jpg (359.04 KiB) Viewed 11826 times

Seal (proper Zexel seal with new rubber sealing O ring from ebay about £10 - £20) aligned

- ByHandMedium.jpg (359.8 KiB) Viewed 11826 times

Pushed home with "proper" instalation tool (no its not a 27mm deep set socket that also fits the injectors Wink )

- SpecialToolMedium.jpg (347.63 KiB) Viewed 11826 times

New seal in... fitted...

- NewSealFittedMedium.jpg (361.48 KiB) Viewed 11826 times

Dont forget not to lose the woodruff key

- WoodruffkeyMedium.jpg (321.25 KiB) Viewed 11826 times

Now time to refit...

get the pump into place... and have the little notch on the timing gear (yes its hard to spot) lined up roughly with the T on the pump.

(top arrow/notch)

- TimingMarksroughlyMedium.jpg (262.5 KiB) Viewed 11826 times

Now align the pump locating dowl with it hole and start to push home...

last minute check the the notched gear tooth is aligned with the T mark (as opposed to the N)

- TimingMarksMedium.jpg (262.43 KiB) Viewed 11826 times

it may not 100% be exact as it has to give a little as the teeth all mesh up

then refit everything...

tip..

fit 2 of the front mounting bolts loose then fit the 2 bolts under the bracket before tightening so you still have play.

I hope that makes sense....

As I said before the idea is to help show those who have the ability but are a bit unsure exactly what to do...

its not hard just do it step by step and you do not need to remove half the engine for access !!

Other things to not..

fuel feed and return lines to pump are different sizes... the feed pipe is bigger so will flop about on the return union.

2 water pipes go to the pump.... one on top one at rear.

Any questions ??

And again thanks to Chiefie for showing me all the above !!!

[/i]